With the advent of state laws that overturn a sixty-year ban on hemp agriculture, a new and yet anciently rooted era of farming is on the horizon. The early adopters who are now backed by legislative and regulatory bodies are Kentucky, Colorado and Washington. This growing season Fibershed is pleased to be working with farmers in two states to see an expansion of our ‘Language of the Landscape Program.’ Our program develops prototypes that lay the technical and aesthetic foundation for artisans and large brands alike. We document and to some degree establish the road-map for how to farm, process and blend homegrown fibers. This work is part historical and contemporary research, combined with on-the-ground experimentation. For each prototyping project, we collaborate with UC Berkeley’s Silver Lab to account for the carbon (soil respiration included) and water footprint from the soil to the skin. Our prototyping research is then open-sourced and becomes baseline knowledge for our biosphere-based fiber system.

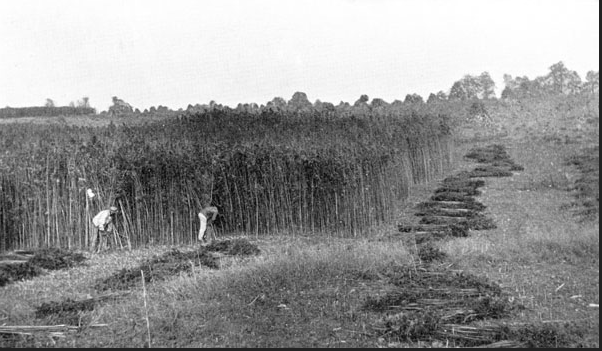

The work of harvesting and processing hemp was known as one of the ‘most difficult jobs in agriculture,‘ according to a 1920s USDA account. Hemp grows densely (70 plants per sq. meter in some cases), and it is sturdy (fiber crops growing 9 to 15 feet in one growing season). It is this sturdiness and density that makes it such an ideal character in the ongoing narrative to re-build and re-imagine a regenerative fiber system. When we look at the pressures on arable farm land—the use of fossil water from ancient aquifers, continuing droughts in the west, and the farm subsidies for conventional GMO corn and soy that dominate our farm belt and eat up our prairies—it is evident that we have some major changes to make to achieve any semblance of a sustainable agricultural system. Hemp offers some key features to a renewable fiber culture. 1) It does not require fossil fuel based pesticides or herbicides. 2) It said to provide up to 8 tons of material per acre (up to 2 tons of textile grade fiber, compared to 70 pounds of wool per acre, or 500 pounds of organic cotton per acre). 3) The plant offers hurd and fiber from one harvest, equalling a suite of products beyond textiles from one growing season. 4) If grown in rotation with wheat, yield increases of up to 50% have been documented and if used to break the alfalfa cycle at years 2 or 3; the alfalfa crop sees a resurgence of growth and density. And yet, it is important to note there are drawbacks to the crop. It’s an annual, and that has historically meant tillage of soils (CO2 emissions), and high labor demands—and in today’s world, labor demands now equate to fuel use. Harvest and processing equipment tend to take the place of laborers, and as we will come to find out as we re-visit our history—the crop requires significant bulk handling to become useful to humans.

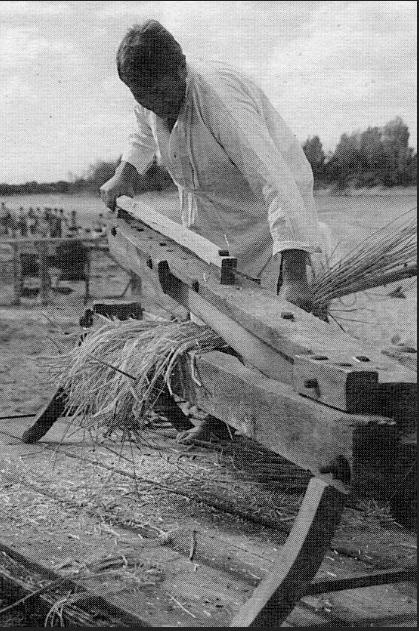

Fibershed is exploring the value chain for fiber production, from the first decortication systems developed in the pre-industrial era, through to modern enzyme and “economy of scale equipment.” We received our first exposure to hand processing by ‘modern-day‘ ancients while in the Loire Valley in France more than 15 years ago. A small and quiet riverside farming community called Montjean continues a hemp farming tradition with the work of Chanvriers. Chanvre is the french word for hemp. Chanvriers are those that process it. More images of the river retting process here.

Due to the United States being 60+ years behind the rest of the world in hemp fiber farming and processing, it is evident that we have significant work ahead of us to build agro-ecology systems and value-addition processes that are both environmentally and economically feasible. Fibershed is beginning its first demonstration and research trials in Colorado. We chose our first site, a high-elevation (7,500 feet), water-constrained location, to experiment with how this crop may or may not suit the needs of agriculture in the West—a region that, as a whole, has been experiencing increasingly long durations of drought. When searching for seeds and experienced collaborators we sought individuals and institutions that could help us source cultivars that would function within this terrain. We built a relationship with hemp plant breeders from Australia to consult us in the process of choosing cultivars and developing a useful research agenda that would advance hemp agriculture for the best possible environmental and economic impact.

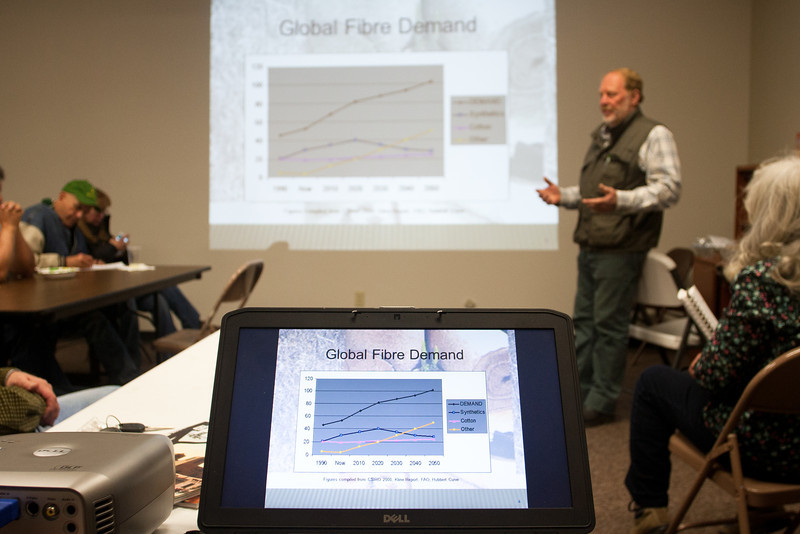

Fibershed sponsored a series of community education events in the San Luis Valley of Colorado to support an increased knowledge base in both the general public and agricultural sectors. Phil Warner of Queensland, Australia (as seen above), describes his 15 years of research with cultivars from around the globe. Here he illuminates the connection between latitude and flowering time. The best way of determining a potentially well-suited cultivar for a new region is to start with a latitudinal match, rather than other correlating factors such as soil-type and water requirements.

Thanks to the efforts of local San Luis Valley residents—Rio de la Vista and County Commissioner Ben Doon—we had a very productive community forum with the County Commissioners of Costilla County and the residents from the surrounding farms and ranches. Costilla County is the site location for our research plots—the region is known as ‘Colorado’s birth place,’ a beautifully remote agricultural community with a track record of developing innovative projects to serve their local population. (A homegrown biodiesel plant and a soon-to-be agricultural institute to provide local food to the public school and elder care center are examples.) We are grateful to have the opportunity to work with this community for this research seed trial. The ‘birth place of Colorado’ may now become one of the ‘birthplaces of Colorado hemp agriculture.’

Our test plots will be planted with two cultivars on county owned lands. To prepare for the planting we spent some time on a very windy March afternoon looking at the soil, and assessing the potential irrigation and soil preparations for the site. Local residents will be hired to administer the farming operation, and collect plant morphology data. This particular site is blessed with a functioning well and water rights that will allow for a smooth growing season.

We spent time at several locations dotted throughout the San Luis Valley assessing other potential planting sites. We analyzed existing equipment for its potential function for hemp farming—looking at seed planters, discing equipment, and other tractor fittings. It was extremely useful to have experienced hemp farming eyes and hands looking at our North American agricultural machinery. Our first stage of research this season (2014) is focused on charting flowering times to assess how these cultivars will grow in our latitude (38 degrees), and in the process we will measure water use, and test the function of local planting equipment. Our second year of research (2015), we will have a sense of which of the two seed types performed best from the year prior, and we will expand into testing more cultivars on two, or possibly three sites, and add variables such as planting date and soil type.

From each site we will hand harvest and process the fiber as was done in the pre-industrial era (we have no highly mechanized options for this at present). We will be building our own hemp breaks, scutching and hackling equipment. Our secondary plans are to send the fiber through a domestic protein fiber milling system and explore the technicalities of blending wool, alpaca and hemp. We have much research to do between now and then on how to build, modify, and retrofit our existing technologies to make this possible. Our planting date in Colorado is May 25th, we will document and share our experience as it unfolds. We will also keep you posted on our ‘second state’ research trial as the images are collected and details become conclusory.

More soon…